Torero

Torero will demonstrate a cost-, resource-, and energy-efficient technology concept for producing bioethanol from a wood waste feedstock, fully integrated in a large-scale, industrially functional steel mill.

Date

From 01/05/17 to 31/05/24

Type

Research project

Status

Started

More information

TORrefying wood with Ethanol as a Renewable Output: large-scale demonstration

Torero will demonstrate a cost-, resource-, and energy-efficient technology concept for producing bioethanol from a wood waste feedstock, fully integrated in a large-scale, industrially functional steel mill:

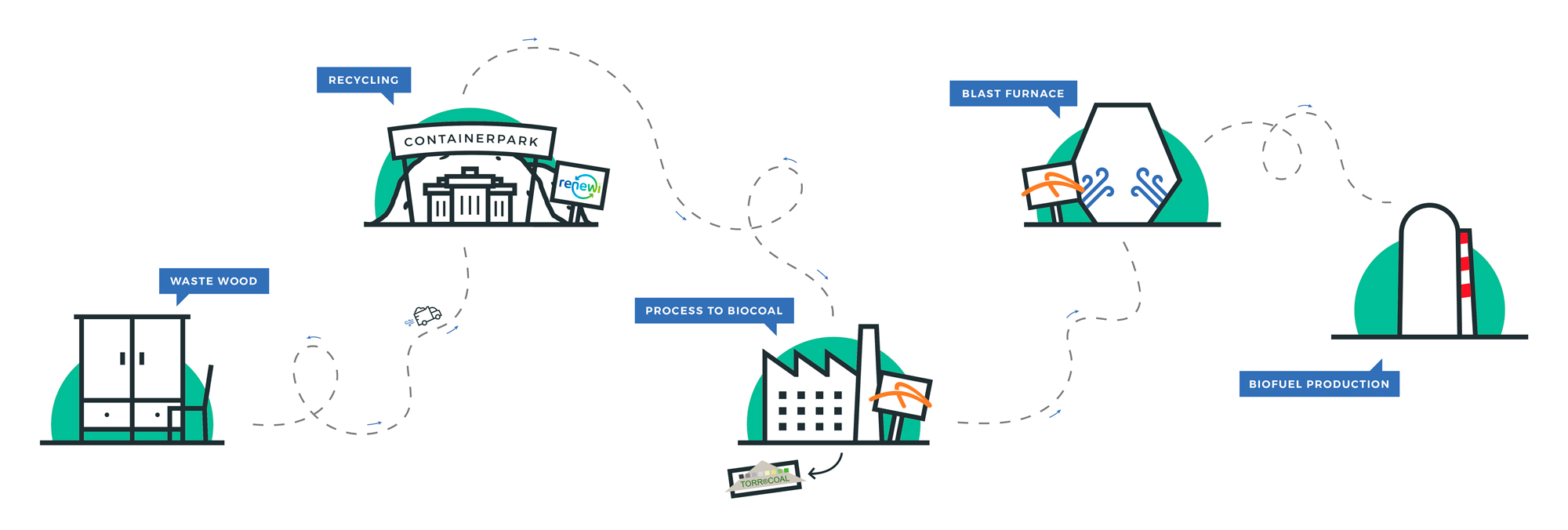

Wood waste is converted to biocoal by torrefaction

Biocoal replaces fossil powdered coal in a steel mill blast furnace

Carbon monoxide in blast furnace exhaust fumes is microbially fermented to bioethanol

Material and energy loops of the process are closed to a very large degree

Every steel mill that implements this concept will be able to produce at least 80 million litres of bioethanol per year. This project creates a value chain for wood waste, which currently has no attractive applications. The technology concept is open ended: in the future, stakeholders may replicate the concept with other feedstocks and for producing other types of fuels.

The business case the Torero project will produce a competitive process for non-food feedstock bioethanol production. Compared with the current first generation production based cellulosic bio-ethanol solution the Torero innovation the OPEX of Torero is 1/3 lower with a same CAPEX. This will allow scale up of torrefaction technology when successfully demonstrated.

Most importantly, together with sister project Steelanol, Torero will be the only H2020 project to demonstrate a biofuel production process that is integrated in an existing, fully functional large-scale industrial facility. All other H2020 solutions will need to be newly built if they ever reach full industrial scale. Torero is add-on technology that can be used to upgrade existing facilities of the steel sector, an industry that is actively scouting for technological solutions to make its production processes more sustainable. The consortium consist of full value chain, industry ArcelorMittal and Van Gansewinkel, two expert research organisations Joanneum Research and Chalmers Technical University and torrefaction technology supplier Torr-Coal.

Host(s)

2 profile(s) associated to this action.

Renewi

RENEWI is a leading waste recovery company that gives new life to used materials every day. They have an extensive network of almost 200 sites across Europe and North America. Waste Collection Belgium is active in the collection, sorting and recycling of hard plastics into secondary raw materials.

Last updated: 29/04/2025

ArcelorMittal Belgium

Steel production company.

Chau. de Ramioul 52, 4400 Flémalle, Belgique

Last updated: 03/02/2026